Computer numerical control (CNC) machines started passing between the Nineteen Forties and Nineteen Fifties. These are electro-mechanical gadgets that acknowlmilling computer programing contributions to manage shop instruments. The underlying models depended on punched tape technology and a while later moved to simple and computer or electronic computer information process system} handling inside the 1950s and 1960s. With CNC Machining Components from machine give organizations, you’ll support shop efficiency as these machines can adjust specialized and work concentrated processes.

Benefits of CNC Machining

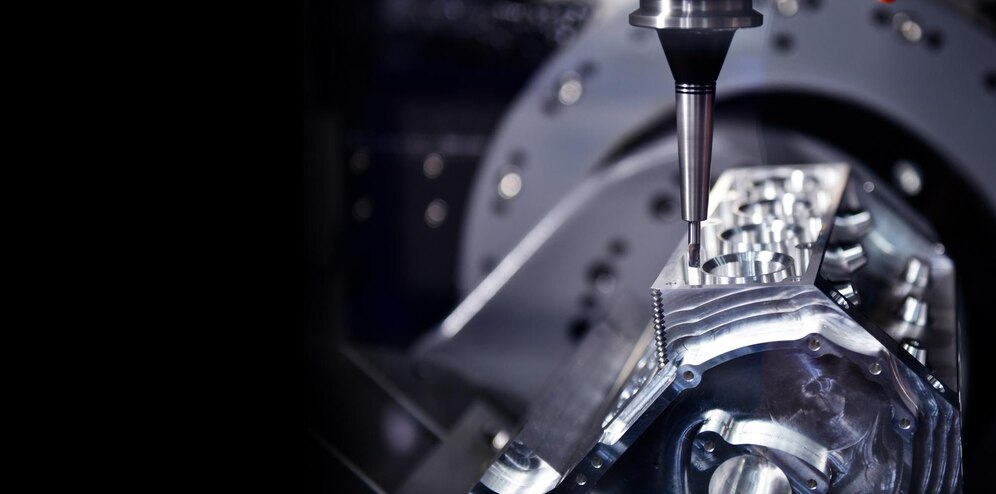

As a rule, machining relies upon a controlled material evacuation cycle to revamp a texture, kind of a block of plastic, to a completed item. Like elective model development technology, CNC machines get computerized headings from a product (CAD) or computer-supported delivering (CAM) record like Solid works 3D to make machine-driven cuts. exploitation CNC machines and Precision Machining Components support each the speed and exactness of cutting model parts. This machining decision is especially useful once processing essential materials, much the same as polypropylene.

Machining frequently includes utilizing numerous gadgets that might be obtained from machine wholesalers to make the expected cuts. With CNC machines, you’ll blend instruments into normal units or cells. For instance, essential machines are many times utilized in one or 2 tomahawks with cutting milling machines making parallel developments inside the x and direction pivot and longitudinal developments in the z-hub. Likewise, high level machines will move rotationally concerning one or extra tomahawks. In the meantime, multi-hub machines can flip components naturally, which recommends you don’t’ got to relegate a representative to flip the model stock material

Sorts of Machines

CNC machines are frequently arranged into two general classes: standard machining and novel machining. CNC machines exploiting traditional machining advances are drills, machines, and milling machines. These are here and there for model development as opposed to assembling. Among all CNC machines, it is in all probability the premier famous to process machines. They need rotating cutting devices to dispose of material from the workpiece.

In the meantime, novel advancements for cutting materials embrace synthetic science machining, supersonic machining, science machining, release machining, bar machining. These very specific strategies are useful for specialty creating methods and creation that needs a specific assortment of material.

Materials

A CNC machine can handle almost any kind of material. The objective application decides the texture to be utilized. CNC machines are frequently utilized for metal, copper, aluminum, titanium, and steel. They will also handle materials like plastic, wood, froth, and fiberglass.

Select one in everything about most elevated machine Distributors

Support Diagnostic Systems, Inc. has collaborated with some of the business’ driving brands to supply long machine devices. As a CNC machine merchant, we might want to supply you with moderate instrumentation to streamline your tasks and lift efficiency. Like that, you’ll cut down costs and increment efficiencies. give America a choice these days to be told more.